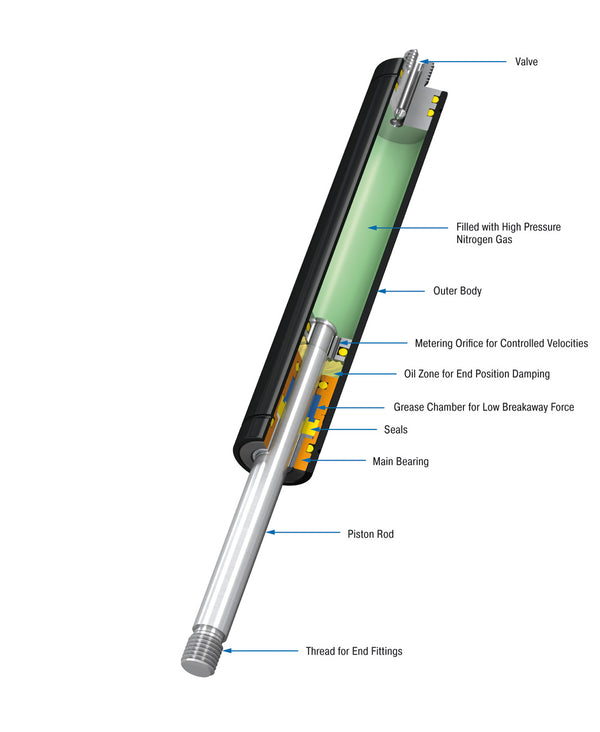

Push Type:

The struts come in body diameters spanning from 8 mm to 70 mm, with forces ranging from 10 N to 13,000 N. A multitude of connections and end fittings, facilitate easy installation, while their lasting performance is ensured by their top-tier design and quality materials. Options include the standard springs for hoods, shutters, machine housings, etc., stainless steel springs in the same sizes but with food grade oil, and tandem springs optimised for heavy flaps and wide-angle applications.

Pull Type:

When tight spaces prevent the use of push type gas struts, ACE’s pull type springs offer the solution. These compact models, with body diameters ranging from 15 mm to 40 mm, use traction, and operating in opposite way to the push type springs. In this design, the gas pressure within the cylinder draws the piston rod inward. The pull type gas springs are also self-contained, maintenance-free and have a valve for adjusting the gas pressure. This allows them to cover forces spanning from 30N to 5,000N. These springs also come with a wide range of mounting options and end fittings.

Since 1963, after developing the first adjustable industrial shock absorber, ACE Controls have grown to become internationally recognised experts in motion control and damping technology. Their ever-expanding product range now covers automation control, motion control, vibration control and safety products.

MacScott Bond has proudly distributed ACE products for decades and can offer Industrial Shock Absorbers, Dampers and Damping plates, Gas Springs, Vibration mounts and anti-vibration construction materials from the Fabreeka™ range.

With ACE we can offer technical and application support on the extensive range of products that are designed to increase production, improve efficiency, prolong operating lifetimes of machinery, and reduce noise, damage, and energy costs