Contact Us for a Free Quote Today

If you have any queries, need a quote for one of our products or want some technical advice from one of our engineers, please get in touch and a member of MacScott Bond will respond as soon as possible.

If you are calling from outside of the UK please call +44 131 448 2950

MacScott Bond's head office in Loanhead, near Edinburgh, is located on the same site as our sister company MacTaggart Scott & Co. Ltd.

We look forward to hearing from you.

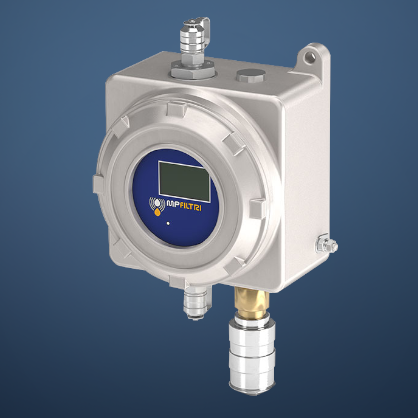

Technical Details for the AZ2

The AZ2, a Fluid Contamination Monitor designed for ATEX Zone 2 environments, Cat 3G, stands out as a reliable solution for automatically measuring and recording particulate contamination, moisture, and temperature levels in hydraulic fluids. This device is specifically engineered to be mounted directly onto systems where continuous measurement or analysis is crucial, especially in high-risk or explosive environments.

Scope of Supply:

1 x ICMKAZ2*

1 x ATEX Approved Non-wired Cable Connector and Gland

1 x Hard copy Fluid Condition Handbook

1 x Digital copy of user guides/software/drivers

1 x Hard copy of calibration certificate

1 x Hard copy of ATEX certificate

(*) Specific model will be as per ordered item

All AZ2 versions feature a multicolour indicator on the front panel, serving as a visual representation of the device's status or alarm state. The alarm thresholds can be customised using the LPA-View software via the serial interface and bespoke connector, available upon request. This ensures adaptability to specific operational requirements, making the AZ2 an ideal choice for environments with high-risk factors or explosive conditions.

| Technology | LED based Light Extinction Automatic Optical Particle Counter |

| Particle Sizing | >4, 6, 14, 21, 25, 38, 50, 70 μm(c) |

| Analysis range | ISO 4406 Code 0 to 25 NAS 1638 Class 00 to 12 AS4059 Rev. E Table 1&2 Sizes A-F: 000 to 12 |

| Accuracy | ± 1/2 ISO code for 4, 6, 14 μm(c) ±1 code for 21, 25, 38, 50, 70 μm(c) |

| Calibration | Individually calibrated with ISO Medium Test Dust (MTD) based on ISO 11171, on equipment certified by I.F.T.S to ISO 11943 |

| Operating Flow Rate | 20 - 400 ml/minute |

| Viscosity Range | Up to 1000 cSt |

| Operating Temperatures | Fluid: -25oC to 80oC Ambient: -25oC to 80oC |

| Pressure | Minimum: 0.5 bar (7.25 psi) Maximum: 400 bar (5802 psi) |

| Test Time | Adjustable 10 - 3600 seconds. Factory set to 120 seconds. Start delay & programmable test intervals available as standard. |

| Flow rate measurement | Indicator only |

| Moisture Sensing | % RH (Relative Humidity) ±3% |

| Temperature Measurement | ±3oC |

| Data Storage | Up to 4000 tests |

| Communication Options | RS485, MODBUS, CANBUS as standard |

| Relays | Two solid state relays fitted to “R” version for output to alarm circuits |

| Environmental Protection | IP66 |

| Current Supply | 12V - 150mA 24V - 80mA 36V - 60mA |

| Supply Voltage | 9 - 36VDC |

| Power Consumption | < 2.2 W |

| Outer Casing Finish | Stainless Steel |

| Wetted Parts | M - C46400 Cu alloy, 316 stainless steel, FPM, FR4, sapphire N - 316 stainless steel, FPM, sapphire. S - 316 stainless steel, perfluoro elastomer, sapphire, EPDM. |

| Software | LPA View software (included) AZ2 is supplied with a full software package and digital product information |

| Dimensions |

Weight: 10.5kg Dimensions: 320mm (H) x 130mm (D) x 186mm (W) |

| ATEX classification |

CE EX 3 G EXnR IIB T5 GC IP66 |

| ICM AZ2 cable wiring details |

MP Filtri do not supply an ATEX approved cable with the ICM AZ2 products as customers may run such cables through varying ATEX zones. Wiring diagrams supplied, please consult product user guide for full information. Note: an adapter cable and ICMUSBi product will be required should LPA View be utilised as the control software. These accessories are only suitable for use outside of the zoned areas |

| Manufacturer | MP Filtri |

Recently viewed

Still not sure? Reach out for expert help on products

If you have any queries, need a quote for one of our products or want some technical advice from one of our engineers, please get in touch and a member of MacScott Bond will assist.

Our History

Founded in 1973, MacScott Bond Ltd has worked for 50 years, ensuring we play our part in providing the engineering excellence expected from being part of the MacTaggart Scott Group. With a rich heritage dating back to 1898, MacTaggart Scott is a trusted name in Scottish engineering, and MacScott Bond proudly upholds this legacy.

The company's commitment to delivering quality fluid power systems is evident through our portfolio of previous projects. MacScott Bond’s designs have stood the test of time and the quality of our construction of bespoke fluid power systems has always been a priority for our company.

From analysing initial requirements, intelligent design and through rigorous testing processes, the company ensures the creation of high-quality systems tailored to the specific needs of diverse sectors, including marine defense, civil, offshore, mining, and industrial.