Contact Us for a Free Quote Today

If you have any queries, need a quote for one of our products or want some technical advice from one of our engineers, please get in touch and a member of MacScott Bond will respond as soon as possible.

If you are calling from outside of the UK please call +44 131 448 2950

MacScott Bond's head office in Loanhead, near Edinburgh, is located on the same site as our sister company MacTaggart Scott & Co. Ltd.

We look forward to hearing from you.

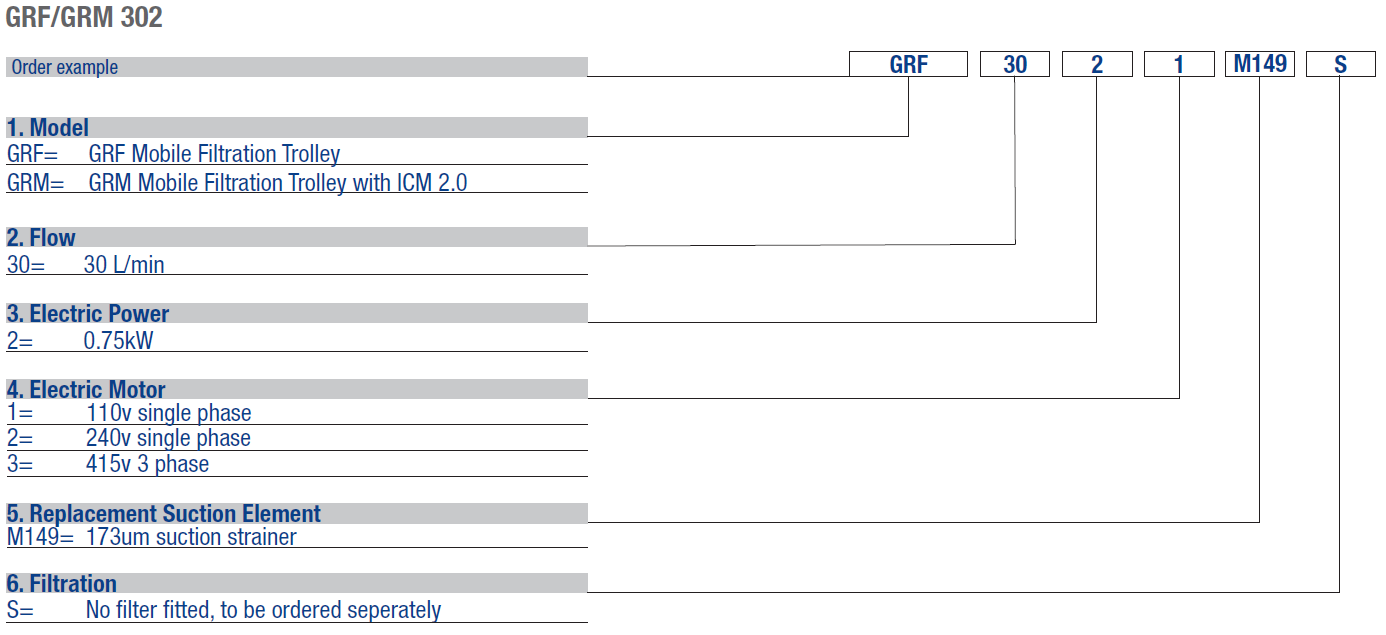

Technical Details for the GRM 302

The GRM 302 Mobile Filtration Unit sets a new standard in oil maintenance, featuring the ICM 2.0 In-line Contamination Monitor. With a robust 30 L/min flow rate and continuous operation at 3.5 bar, it excels in filling and filtering hydraulic fluids and lubrication tanks. Connectable off-line to tanks (recommended max volume 500 L), it supports fast flushing during start-up and serves as additional filtration for highly contaminated systems. Compact in size and calibrated to ISO standards, it ensures precise performance. Equipped with MPS100 filter as standard, optional LMP4305 filter, electric control box, and real-time monitoring with data logging capabilities.

This encourages regular oil maintenance to protect sensitive components and the machine as a whole from excessive contamination. These trolleys are a great asset to have around your hydraulic systems as they offer a great way of filtering fluids as you fill your tank.

Designed and manufactured by MP Filtri, the GRM 302 series of mobile filtration units are designed for service teams to clean hydraulic systems quickly and easily.

| Pump | Gear Pump or Screw Pump (for diesel) |

| Electric Motor | 0.75kW, 1400rpm, 110/240 Volt Single Phase, 415V three-phase |

| Flow Rate | 30L/min |

| Max Operating Pressure | 3.5 bar |

| Viscosity Range | Max. 150 cSt |

| Inlet Filter | 100 µm mesh washable as standard |

| Outlet Filter | 1/3/6/10/25 μm ß>1000 flow through the element Out/In |

| Bypass Indicator set at 1.75bar | Rating 3.5 bar with bypass (LMP) 1.75 bypass (MPS) Visual/electrical indicator (on LMP) set at 2 bar |

| Operating Temperatures | Fluid: -10oC to 80oC Ambient: 0oC to 45oC |

| Protection Class | IP 55 |

| Seal | NBR |

| Fluid Compatibility | Mineral Oil and diesel oil variants |

| Suction / Pressure Hose | SAE100R4 1" swaged female 2000mm hose (available with lances) |

| Dimensions | Weight: 80kg Dimensions: 860mm (H) x 560mm (D) x 500mm (W) |

| Equipment | |

| Manufacturer | MP Filtri |

| Filter element - Standard length: Inorganic microfiber element | CS 100 A01 A P01 - 1 μm absolute CS 100 A03 A P01 - 3 μm absolute CS 100 A06 A P01 - 6 μm absolute CS 100 A10 A P01 - 10 μm absolute CS 100 A25 A P01 - 25 μm absolute |

| Filter element - Standard length: Wire-mesh element | CS 100 M25 A P01 - 25 μm CS 100 M60 A P01 - 60 μm |

| Filter element - Extended length: Inorganic microfiber element | CS 150 A01 A P01 - 1 μm absolute CS 150 A03 A P01 - 3 μm absolute CS 150 A06 A P01 - 6 μm absolute CS 150 A10 A P01 - 10 μm absolute CS 150 A25 A P01 - 25 μm absolute |

| Filter element - Extended length: Wire-mesh element | CS 150 M25 A P01 - 25 μm CS 150 M60 A P01 - 60 μm |

Recently viewed

Still not sure? Reach out for expert help on products

If you have any queries, need a quote for one of our products or want some technical advice from one of our engineers, please get in touch and a member of MacScott Bond will assist.

Our History

Founded in 1973, MacScott Bond Ltd has worked for 50 years, ensuring we play our part in providing the engineering excellence expected from being part of the MacTaggart Scott Group. With a rich heritage dating back to 1898, MacTaggart Scott is a trusted name in Scottish engineering, and MacScott Bond proudly upholds this legacy.

The company's commitment to delivering quality fluid power systems is evident through our portfolio of previous projects. MacScott Bond’s designs have stood the test of time and the quality of our construction of bespoke fluid power systems has always been a priority for our company.

From analysing initial requirements, intelligent design and through rigorous testing processes, the company ensures the creation of high-quality systems tailored to the specific needs of diverse sectors, including marine defense, civil, offshore, mining, and industrial.